In commercial HVAC, air handlers or air handling units (AHUs) are used to circulate conditioned air throughout a space. In this article, we will explain the concept behind air handlers, and explain how air handlers work.

After we explain how air handlers work, we’ll go over a few examples of air handlers. We will also look at the different components that make up an air handler.

What is an Air Handler?

Simply put, air handlers are devices used to create conditioned air, and move that air throughout a space. Air handlers come in many shapes and sizes, but commonly take the form of a fan, filter, and coil enclosed in a large metal box. They are used to condition the air inside of a space.

The key distinction of an air handler is that its only job is to clean and condition air. Technically, an air handler does not need to provide the source of heating or cooling, it only cleans and conditions the air.

How does an Air Handling Unit work?

In its simplest form, an air handler consists of a fan blowing air through a filter and heat exchanger.

Here is how an air handler works:

- The air handler’s blower draws return air from an enclosed space within a building, such as an office, hallway, or classroom. Most air handlers also bring in some outside air – this is to ensure that there is always clean, fresh air in the space, and not the same recycled air over and over again. It is important to bring in fresh air to a space to prevent high CO2 levels and stale air.

- The return air and outside air both come into an area of the AHU called a mixing plenum. The mixing plenum is a compartment where the two airflows mix together before passing through the rest of the air handler.

- Next, the air passes through a filter. As the air passes through the filter, particles get trapped in the filter and are removed from the air stream.

- Next, the air passes through the heat-exchanging coil. The heat exchanger cools or heats the air in the process, depending on the type of air handler, which I’ll talk more about below.

- Lastly, the clean, conditioned air is pushed out of the air handler into the enclosed space.

Air Handler Types

Here are two examples of types of air handlers:

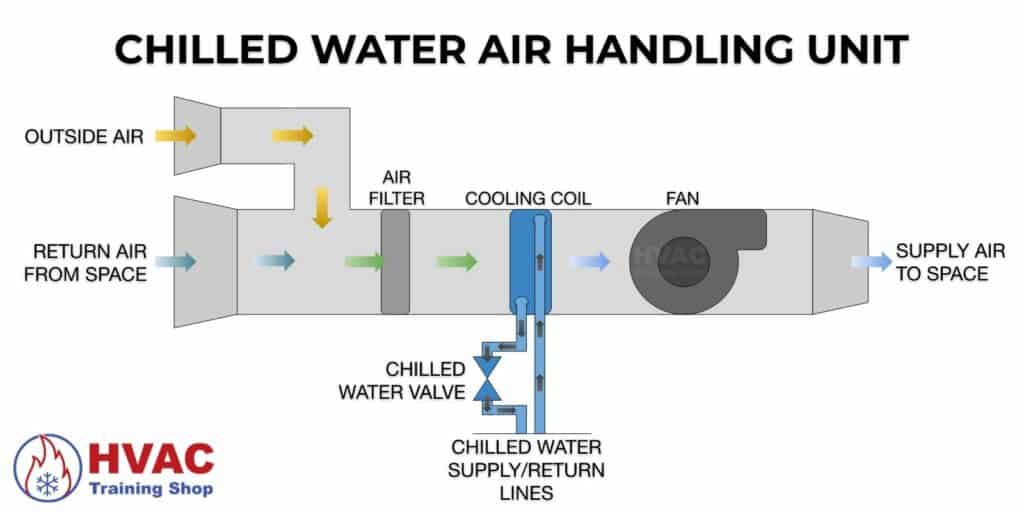

- Hydronic air handling units have water that flows through the coil. The water can either be hot or cold depending on if the air handler is heating or cooling a space. As the water flows through the coil, the coil changes temperature. The fan blows air over the coil, and the air is heated or cooled by the coil.

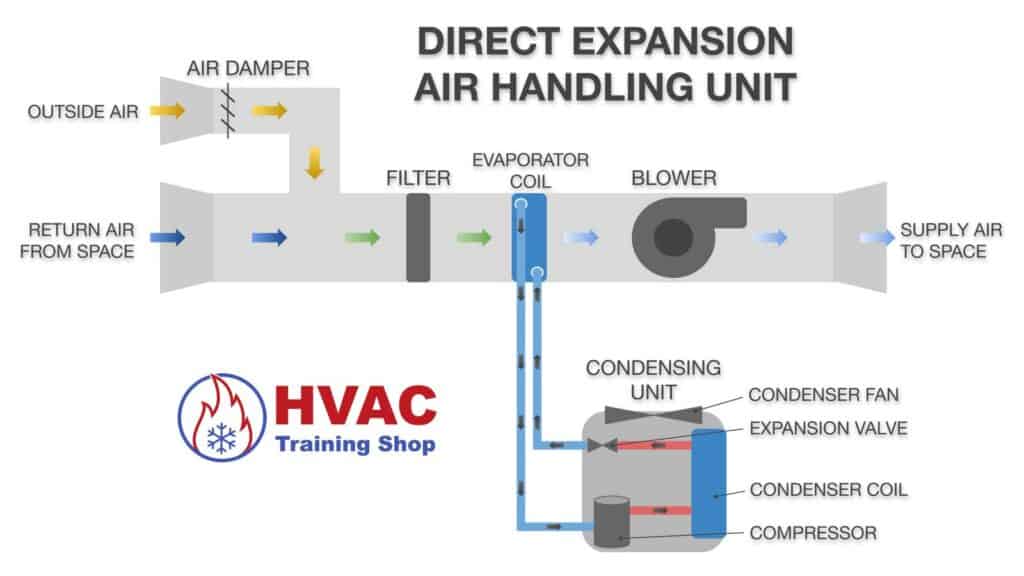

- Direct expansion (DX) air handling units have refrigerant that flows through the coil. The refrigerant directly exchanges heat with the air blown by the fan.

The parts of an Air Handler

There are a few critical parts that are found in almost every air handler. Every air handler has, at a minimum, a fan, a coil, a filter, and a few other components:

Air Handler Fan

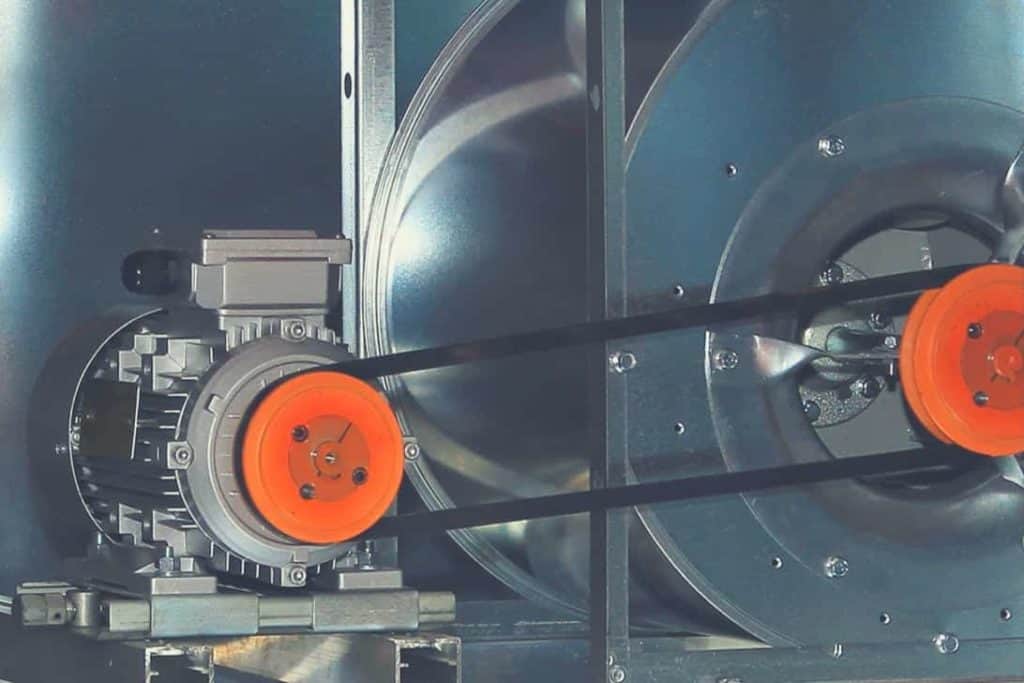

The purpose of the fan is to move air through the air handler. For this reason, the fan is often seen as the “heart” of the air handler.

The fan is also commonly referred to as a “blower”.

Most air handler fans are centrifugal fans. Centrifugal fans are capable of generating the high air pressures that are needed to distribute air throughout remote spaces.

Centrifugal fans are sometimes referred to as “squirrel cage fans” due to their similar appearance to a hamster wheel.

While all air handlers have at least one supply air fan, some air handlers have a return air fan as well.

Return air fans are commonly found in larger air handlers. The return air fan aids in sucking the air out of the space into the air handler.

Return air fans are used when the air handler needs to overcome high pressures to get the air from the space back into the air handling unit.

Air filter

The air filter’s job is to clean the unconditioned air as it is sucked from the interior space or the outside.

The filter is usually placed before other components such as the coil and fan. This is to ensure that the air is cleaned before interacting with any other components in the air handler, such as the blower or heat exchanger.

Why does an air handler need a filter?

Dust, dirt, and grime can build up inside your air handler and cause all kinds of problems. If a filter is not used, dirty air goes through the air handler, and will eventually degrade the performance of the air handler.

The air filter also serves to remove particles from the air you breathe, so only clean air flows into your home. Using an air filter that is not efficient enough can cause respiratory issues, especially if you have pets or allergies.

Depending on the application, there may be more than one set of filters that the air passes through. It is common for an air handler to include a pre- and final-filter setup, where a less efficient air filter is used to clean the air before it passes through a high-efficiency final filter.

Some air handlers include differential pressure monitoring devices to measure the pressure drop across the filters. The dirtier a filter gets, the higher the pressure drop.

High-MERV filters also cause reduced airflow. The pressure drop across the filters should be monitored since a high pressure drop can cause reduced efficiency of the air handling unit.

Heat Exchanger Coil

The purpose of the air handler coil is to condition the air that passes through it. There are many different types of heat exchangers, in various shapes and sizes. But they can generally be divided into two categories, depending on how they exchange heat.

There are two different types of heat exchangers:

- Direct heat exchangers work by exchanging heat directly with the combusted gas or refrigerant working fluid. Electric heaters are also considered direct heat exchangers.

- Indirect heat exchangers utilize an intermediate fluid such as chilled water or steam to condition the air. In this case, the intermediate fluid is used to transfer heat from a remote system that heats or cools the water by combusted gas or refrigerant.

Heat exchangers are typically constructed of copper or aluminum, with fins protruding from the surface of the coil.

The fins aid in the transfer of heat from the fluid to the air stream. The shape of the coil usually includes several turns or bends to allow for maximum heat transfer from multiple passes.

As fluid moves through the interior of the coil, the fins aid in heat transfer to or from the fluid to the air, depending if it is a heating or cooling coil.

The fluid in cooling coils flows in the opposite direction of the airflow. This is called a counterflow arrangement.

If the fluid in the coil is chilled water or hot water, the water that enters the coil is fed from the bottom of the coil and leaves through the top. This is to ensure that air is bled out of the system since the air will rise due to its density.

If the fluid in the coil is steam, then the steam should enter from the top of the coil to ensure that any condensate flows downward and does not impede the flow of steam.

Control Valve

The purpose of the valve is to control the amount of water or gas that flows through the coil. For example, the more chilled water flow that flows through the coil, the colder the coil gets, and the colder the air gets as it passes through the coil.

Valves are typically controlled by an electronic actuator that opens or closes the valve, depending on the temperature inside of the space.

Other times the valve will modulate to maintain the same supply air temperature to the space, while the fan changes speed to maintain the temperature inside the space.

For example, a chilled water air handling unit might control its valve to maintain 55°F supply air into a space. If the space gets too cold, the fan will slow down to deliver less volume of air to the space to maintain the space’s temperature.

Air damper

The purpose of the damper is to control the amount of airflow going through the air handler.

Manually adjustable dampers are usually placed in the ducts or on the vents in the space. These dampers can be used to balance the amount of airflow that flows in and out of the space.

Some dampers have actuators that can automatically open or close. These modulating dampers will adjust their position to maintain a precise amount of airflow.

Modulating dampers are typically placed on the outside air intake of the air handler – this damper is used to control the amount of outside air that goes into the air handler.

Ductwork

While not directly part of the air handler, most air handlers incorporate some kind of ductwork into their design. Ductwork are passages that are used to move air between the air handler and the conditioned space.

Ductwork serves as the “pipe” that connects the air handler to the space that it is conditioning. Therefore, it must be able to withstand the pressures associated with transferring large volumes of air.

Ductwork is commonly made out of sheet metal – sheet metal is fairly rigid and can maintain its shape.

Flex duct is a long tube that easily fits into awkward spaces. It is commonly used in the final length of ductwork that transfers air to a space.