Fan coil units are used in all types of buildings – from residential to commercial to industrial – even the local bar down your street might have a fan coil unit.

Fan coil units come in all shapes and sizes – but no matter where a fan coil unit is used, or what shape it comes in, its working principle is exactly the same.

In this article, I’ll explain how a fan coil unit works by first going over the basics of fan coil units. I’ll also provide some examples of different types of fan coil units and explain how the different types of fan coil units compare to each other.

Fan Coil Unit Basics

A fan coil unit works by using a fan to move air through a heating or cooling coil to condition the air in a space.

In its simplest form, a fan coil unit consists of a fan and a coil:

- Fan: The fan is used to circulate air through the fan coil unit and the conditioned space. The fan sucks air out of the room, through the fan coil unit, and blows it back into the room.

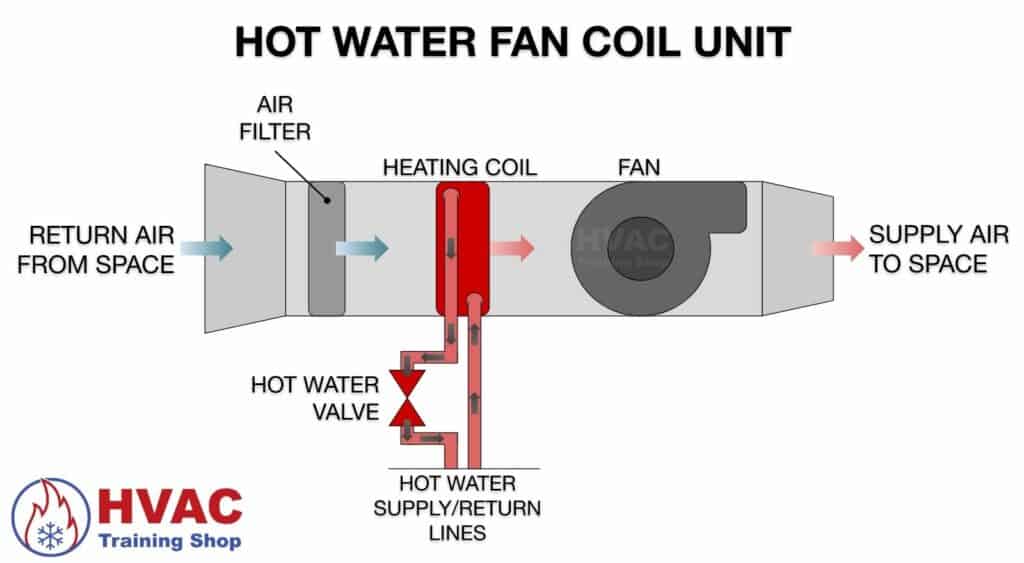

- Coil: The coil is used to heat or cool the air as it passes through the fan coil unit. In commercial buildings, the coil is usually connected to a hot water or chilled water system.

Most fan coil units have an air filter as well.

The air filter is used to filter particulates out of the air before they enter the fan coil unit. The air filter helps protect the fan coil unit’s internal components from dust and also cleans the air in the conditioned space.

Fan coil units usually aren’t connected to a larger ductwork system, but they may be in some cases.

The key defining factor of a fan coil unit is that it only recirculates air in a given space. If the unit uses its fan to bring in any outside air, then the unit is technically not a fan coil unit – it’s an air handler.

In commercial HVAC, a fan coil unit is actually a specific type of air handler that uses a fan to recirculate the air in a space and a coil to heat or cool the air as it passes through the unit.

In residential HVAC, the term fan coil unit is used loosely and is used to name units that have at least a fan and coil, regardless of whether it brings in outside air or not.

I go over all of the differences between air handlers and fan coil units in my fan coil unit versus air handling unit article.

Fan Coil Unit Types

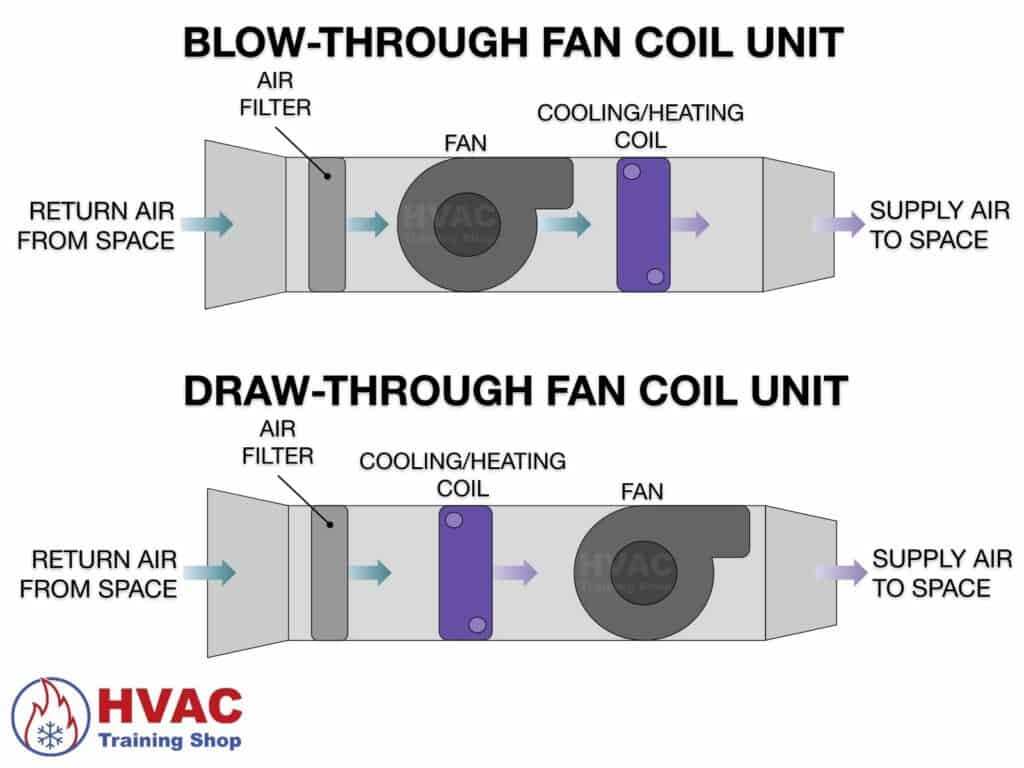

Every fan coil unit can be classified into two general types based on the location of its fan:

- Blow-through. A blow-through fan coil unit’s fan is upstream (behind) the coil. The fan blows air through the heat-exchanging coil.

- Draw-through. A draw-through fan coil unit’s fan is downstream (in front) of the coil. The fan sucks air through the heat-exchanging coil.

There are pros and cons of both blow-through and draw-through fan coil units. Generally, draw-through fan coil units are preferred for cooling and dehumidification purposes.

You can also classify a fan coil unit based on what flows through its coil:

- Refrigerant. If refrigerant flows through the coil, then it’s considered a direct-expansion fan coil unit.

- Water. If water flows through the coil, then it’s considered a hydronic fan coil unit.

In a direct expansion fan coil unit, the coil serves as the evaporator or condenser in the refrigeration cycle. An example of a direct expansion fan coil unit is the indoor unit for a split system air conditioner.

In a hydronic fan coil unit, chilled water or hot water flows through the coil to cool or heat the space. Hydronic fan coil units are usually only used in large buildings with centralized heating and cooling systems. The water is cooled or heated in a separate system – such as a chilled water system or a boiler system.

When it comes to hydronic fan coil units, there are two main types:

- 4-pipe fan coil units

- 2-pipe fan coil units

I’ll go over them below.

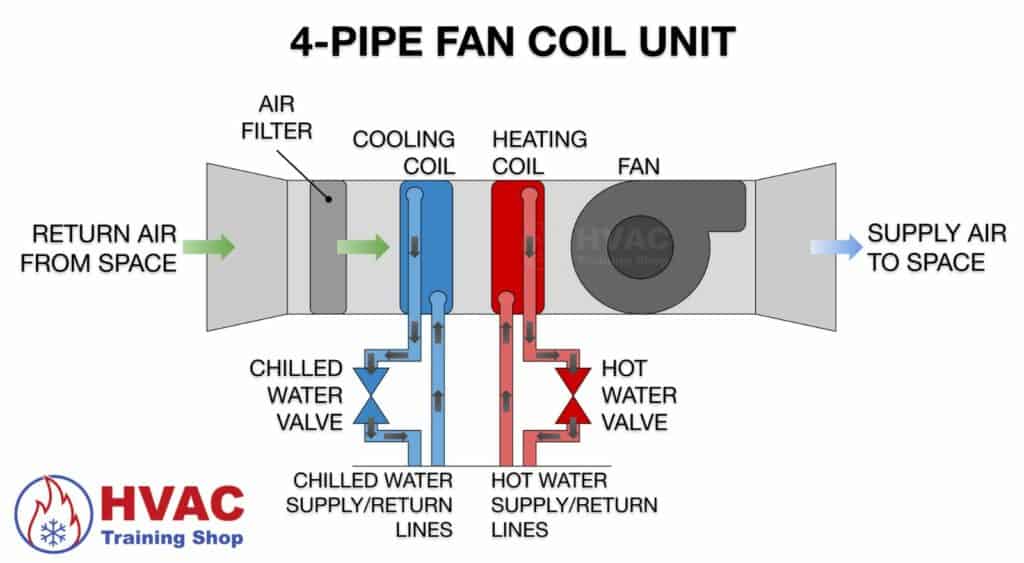

How a 4-pipe fan coil unit works

A 4-pipe fan coil unit has two coils – a cooling coil and a heating coil. Each coil is connected to two pipes – one pipe for the water supply and another pipe for water return.

Both cooling and heating coils have their own individual valves – so there are separate cooling and heating valves.

The cooling valve opens if cooling is required in the space. The heating valve opens if heating is required in the space.

The main advantage of using 4-pipe fan coil units in an HVAC system is that the cooling and heating coils are separate from each other, allowing for simultaneous heating and cooling throughout the building.

For example, if one part of a building needs cooling but the other part of the building needs heating, a 4-pipe system will allow some fan coil units to cool the building and the other fan coil units to heat the building at the same time.

Another advantage of a 4-pipe fan coil unit is that it can dehumidify a space. A 4-pipe fan coil unit can use its cooling coil to remove moisture from the air, then use its heating coil to reheat the air. This allows for simultaneous dehumidification and temperature control in a space.

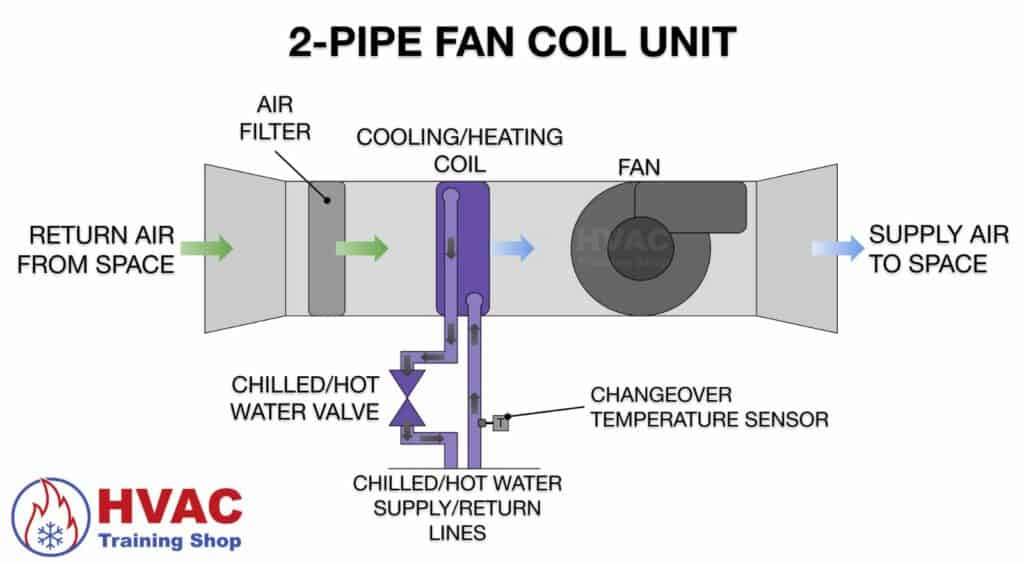

How a 2-pipe fan coil unit works

A 2-pipe fan coil unit has one coil connected to two pipes. One pipe is for the water supply and the other pipe is for water return.

Chilled water or hot water flows through the coil, depending on whether cooling or heating is required in the building.

The flow through the coil is controlled by a valve on one of the pipes. The valve opens and closes depending on the heating or cooling demand in the space.

The main advantage of using 2-pipe fan coil units in an HVAC system is that they are cheaper to install. There is less labor and material used (pipes, fittings, valves, etc.) to install a 2-pipe fan coil unit when compared to a 4-pipe fan coil unit.

But how does a 2-pipe fan coil unit know if it has chilled water or hot water flowing through its pipes? Wouldn’t it be a huge mess if the valve opened up when trying to cool the space – but instead hot water flowed through the coil?

Fortunately, the 2-pipe fan coil unit is able to detect whether it has chilled water or hot water flowing through its pipes by using a changeover temperature sensor.

The changeover temperature sensor is attached to the water supply pipe and measures the temperature of the water in the pipe.

The purpose of the changeover sensor is to detect whether chilled water or hot water is flowing through the pipe:

- When the changeover sensor detects hot water flowing through the pipe, the fan coil unit’s control board goes into heating mode and opens the valve if heating is required in the space.

- When the changeover sensor detects chilled water flowing through the pipe, the fan coil unit’s control board goes into cooling mode and opens the valve if cooling is required in the space.

Can you please clarify a FM statement made to all occupants in a high rise Middle East Tower block which we believe is false scare mongering marketing to drum up business. Our units have a metered chilled water to a draw through FCU unit with a On/Off 2 port valve. The FM claim a dirty filter and coil consumes more chilled water. Q1).My understanding is the dirty coil increases the fouling factor taking longer for the energy to be transferred from the inside of the coil to the coil offside air and as “energy cannot be created or destroyed” it has nowhere to go other than from the inside of the coil to the airside of the FCU where both chilled water temperature are metered a short distance away. The lower heat transfer requires a longer running time where the only loss on the chilled water side is the chilled water pipework losses for this extra running time. Is this correct or have I got this wrong. The other factor is the fan efficiency operation point consuming more electricity and running time which is marginal.

Hi Sledge,

How is the building metering your chilled water usage? You are correct that the energy transfer has nowhere to go other than the coil. If your energy usage is metered using chilled water flow and chilled water supply/return temperatures, then the chilled water energy losses for you are minimal.

However, if the building is metering strictly based on chilled water flow, then maximising the heat transfer ability of your FCU’s coil would be beneficial.

-Trey