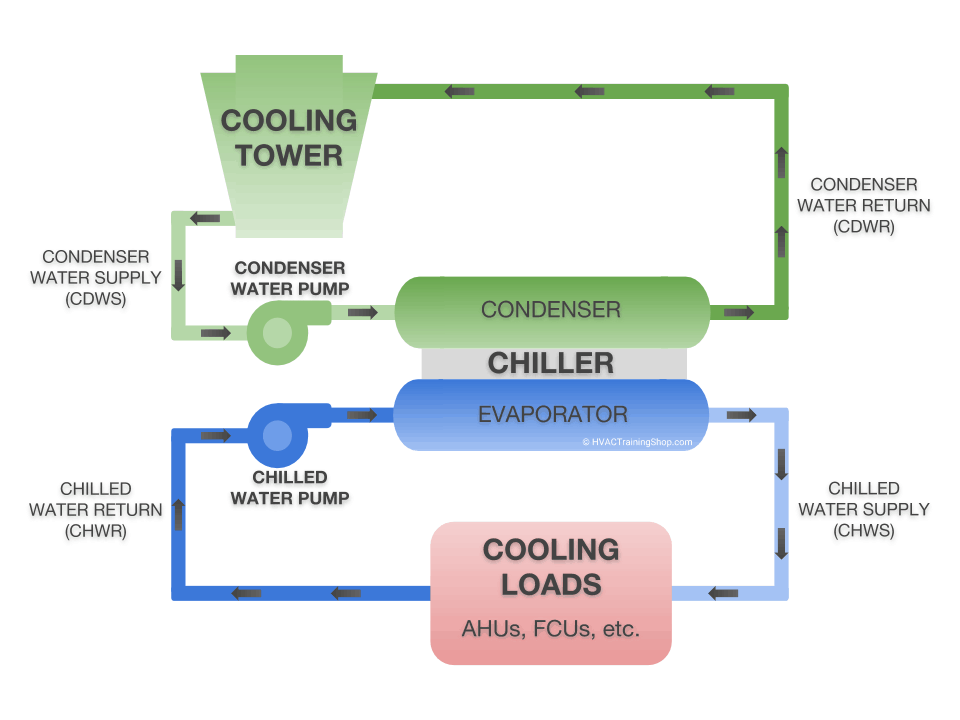

Large centralized AC systems require heat rejection to the outside of the building. This heat rejection is obtained by the use of a cooling tower.

A cooling tower is a device that rejects heat to the atmosphere by cooling a working fluid (typically water) to a lower temperature.

In a chiller plant, this water is part of the condenser water loop, and is responsible for removing heat from the chiller, and rejecting it to the outside atmosphere.

Cooling towers are usually found on the top of large buildings that have central AC systems. If a building has a water-cooled chiller, then there is a good chance that it has a cooling tower outside.

In this article, I’ll discuss how a cooling tower works. I’ll also go over a few different types of cooling towers and the parts of a cooling tower.

How does a Cooling Tower work?

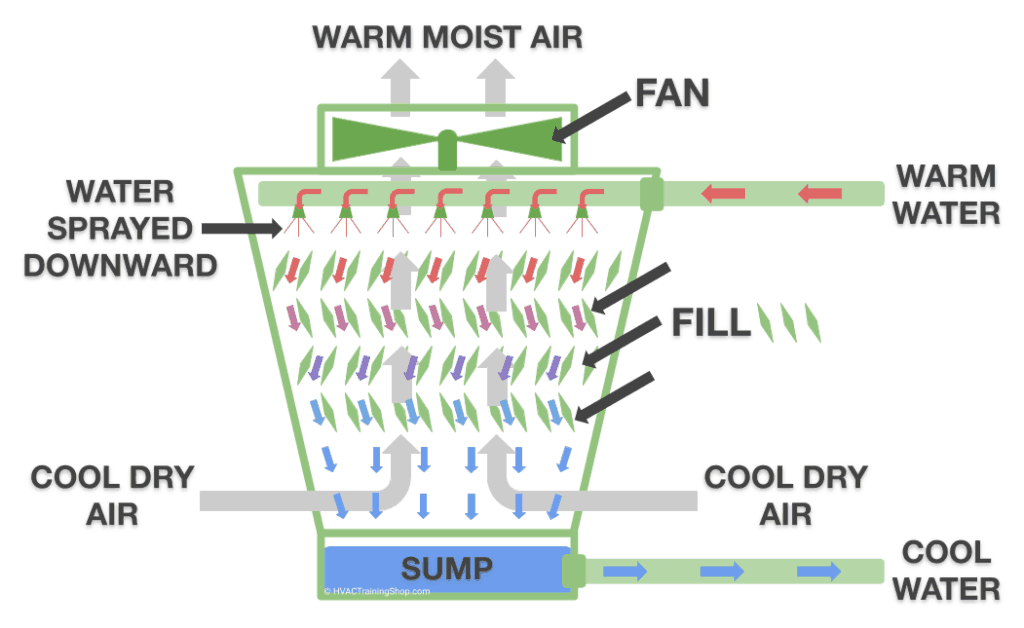

Cooling towers work by using air to cool a working fluid (water).

There are primarily three different methods in which a cooling tower can remove heat from water:

1. Direct cooling – Open-loop

Open-loop cooling towers work by bringing the working fluid water into direct contact with the air.

As the cool, dry air comes into contact with the warm water, some of the water evaporates, producing an evaporative cooling effect.

When some of the water evaporates, it removes a large amount of heat with it.

Because the water comes into contact with the outside atmosphere, this is known as an open-loop system.

2. Indirect cooling – Closed-loop

Indirect Closed-loop cooling towers are similar to direct cooling open-loop systems.

In an indirect closed-loop cooling tower, the water that is being cooled never comes into direct contact with the surrounding air.

Instead, the water flows through a coil in a closed-loop system.

To remove heat, a separate, open-loop system flows over the coil to remove heat from the water in the closed loop.

3. Direct Cooling – Closed Loop

This is similar to the indirect cooling closed-loop system, in that the water that is being cooled flows through a heat exchange coil in a closed-loop system.

To remove heat, air flows over this coil and takes heat away from the water inside.

This is the only method that does not use evaporative cooling to remove heat.

Classification of cooling towers

Now that I have discussed the different heat exchange methods of cooling towers, I’ll go over the specifics of how cooling towers remove heat from the water.

Classification of cooling towers by airflow generation method

All three methods of heat removal in cooling towers require airflow to remove heat from the working fluid (water).

However, there are a few different methods that are used to achieve the airflow movement that is required for heat removal.

Natural draft

This is the simplest form of airflow generation.

There are no fans or anything of that sort in a natural draft cooling tower.

Natural draft is achieved by utilizing the lower density of warm, moist air.

The warm, moist air rises naturally upward and out of the cooling tower, inducing an upward current of air through the cooling tower.

Mechanical draft

Mechanical draft cooling towers utilize fans to move air through the cooling tower. There are two types of mechanical draft:

- Forced draft. A forced draft cooling tower has a fan at the cooling tower’s air intake. The fan blows air into the cooling tower.

- Induced draft. An induced draft cooling tower has a fan at the cooling tower’s air discharge. The fan sucks air into the cooling tower.

Forced draft cooling tower pros:

- Able to work with high static pressures, so can be installed in tight spaces where airflow may be restricted.

Forced draft cooling tower cons:

- Airflow exiting the cooling tower is at a low velocity, so it can be prone to recirculating back into the tower, reducing the tower’s efficiency.

- The fan can be damaged if the atmospheric air is too cold since the fan is on the inlet of the cooling tower.

Induced draft cooling tower pros:

- Airflow exiting the cooling tower is at high velocity, so there is less chance of recirculating back into the tower.

Induced draft cooling tower cons:

- Needs to be installed in a large open space.

- Can sometimes be very noisy.

Classification by Direction of Air-to-Water Flow

You can also classify cooling towers based on the direction that the atmospheric air interacts with the fluid in the cooling tower.

Crossflow cooling tower

In crossflow cooling towers, the water flows downward vertically through the cooling tower.

The air flows horizontally through the fill in the cooling tower.

The atmospheric air interacts with the water flow in the cooling tower in a perpendicular direction.

Counterflow cooling tower

In counterflow cooling towers, the water flows downward vertically through the cooling tower

The air flows upward vertically through the fill in the cooling tower.

The atmospheric air interacts with the water flow in the cooling tower in a parallel, but opposite direction.

Parts of a cooling tower

Compared to other equipment in HVAC, cooling towers are relatively simple machines that are easy to understand.

There is a minimal amount of moving parts in a cooling tower. Usually, the fan is the only moving part.

Cooling tower fan

Mechanical draft cooling towers have fans.

The purpose of the cooling tower fan is to induce a draft through the cooling tower to aid in heat transfer.

In forced draft cooling towers, the fan can be either axial or centrifugal.

In induced draft cooling towers, the fan is always axial.

Most cooling towers are induced draft with an axial fan.

Heat exchanging coil

Closed-loop cooling towers have a coil that the working fluid (water) flows through.

The purpose of the coil is to cool the working fluid that flows through the inside of it.

A coil consists of a pipe with thin fins around it to absorb heat efficiently.

In a closed-loop system with indirect cooling, a separate open-loop system flows over the coil to cool the working fluid inside of the coil.

Fill

In an open-loop cooling tower, fill is the primary surface that facilitates the transfer of heat from the water to air.

Fill works by dispersing the water so there is as much surface area as possible to aid in heat transfer.

Fill is usually made of some type of plastic such as PVC or polypropylene. There are two types of fills in cooling towers:

- Splash Fill. Splash fill works by disintegrating the water into smaller and smaller drops. More drops = more surface area = more heat transfer.

- Film Fill. Film fill works by grooming the water to flow down through the cooling tower in a thin, wide film. Thinner film = more surface area = more heat transfer.

Drift eliminator

Drift eliminators are usually installed on the perimeter of the cooling tower, around the fill.

The purpose of the drift eliminator is to reduce the loss of already-cooled working fluid to hot air in the atmosphere.

Water treatment system

The purpose of the water treatment system is to remove minerals from the water to prevent scaling and fouling of the cooling tower.

Additionally, water treatment systems usually have filtration to remove particulates.

Treatment systems also have chemicals to prevent the growth of biological organisms such as algae.