HVAC Training Shop is reader-supported. As an Amazon Associate, I earn from qualifying purchases.

If you have been shopping for air filters, you’ll notice that the Filtrete filters from 3M use the MPR rating system.

But what is the MPR system anyway? And how does it compare to the MERV system?

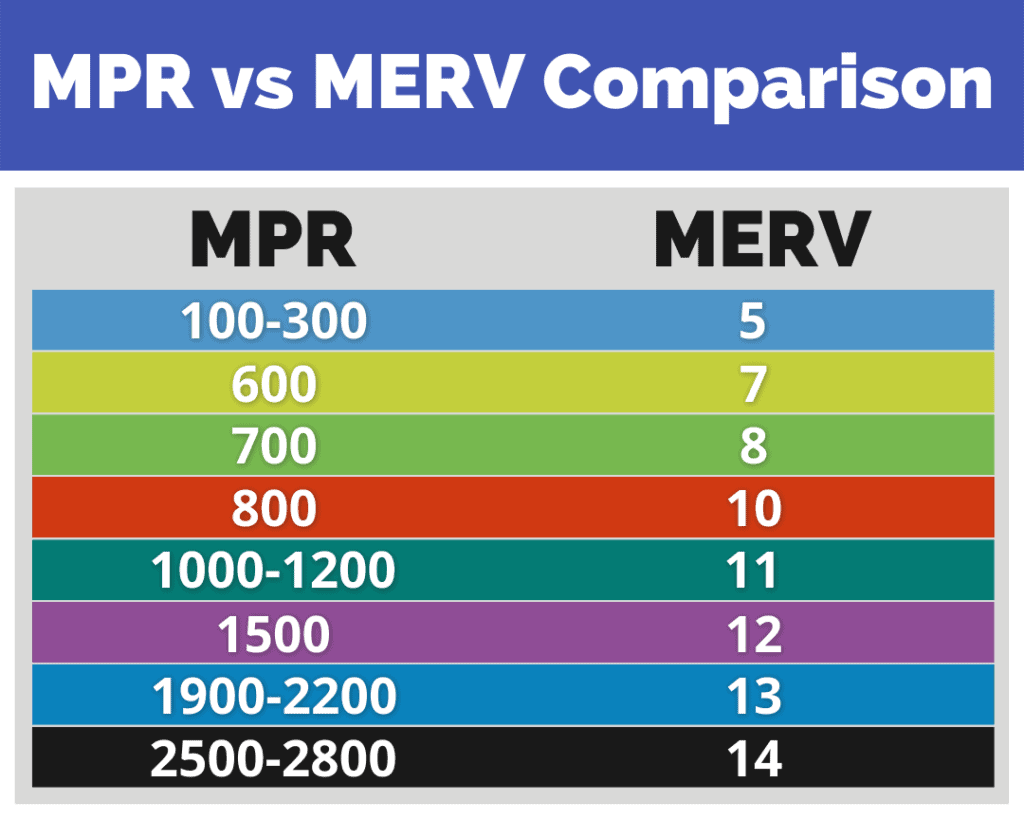

The difference between the MERV and MPR systems is that the MERV system uses a scale of 1-16, while MPR uses a scale of 100-2800.

The MERV system rates air filters on their ability to capture 3 different sizes of particles. The MPR system is focused on measuring a filter’s effectiveness at capturing the tiniest particles – E1 particles.

In this article, I’ll go over the differences between the MERV and MPR systems. I’ll also cover the differences between MPR ratings, and discuss the best MPR rating to use in your home.

MERV versus MPR rating comparison

Even though MERV and MPR are different rating systems, they are directly comparable to each other.

The MERV rating system is the industry-standard rating system. It was established by the American Society of Heating, Refrigerating, and Air Conditioning Engineers (ASHRAE).

The MPR rating system was created by 3M to measure an air filter’s effectiveness at filtering out microparticles.

The MERV rating system establishes minimum percentages of particles that a filter must trap in order to obtain a MERV rating. For example, a filter with a MERV rating of MERV-13 must be able to trap at least 50% of E1, 85% of E2, and 90% of E3 particles.

The MPR rating system is focused on measuring a filter’s effectiveness at capturing the tiniest particles – E1 particles. For instance, an MPR 1000 filter is able to filter 41% of E1, 77% of E2, and 88% of E3 particles.

What does MPR mean?

MPR stands for Microparticle Performance Rating. The MPR system was created by 3M and is designed to measure an air filter’s filtration of microparticles.

The MPR system uses a scale of 100-2800, with 100 being the lowest performance, and 2800 being the highest.

The MPR system focuses on measuring a filter’s efficacy for particles in the 0.3-1.0 micron range.

For instance, a filter with a rating of MPR 2200 is able to remove 69% of E1 particles in the 0.3-1.0 micron range.

However, it is not clear what 3M’s guidelines are for giving different filters a specific MPR rating. This means that we don’t know exactly what threshold must be met by an air filter to obtain a certain MPR rating.

What is the highest MPR rating for an air filter?

The highest air filter MPR rating is 2800.

However, that doesn’t mean that you should go out and get the highest MPR rating for your HVAC system.

The highest MPR rating isn’t necessarily the best for your AC or furnace.

High MERV and MPR ratings generally mean less airflow through your HVAC system. This means you’ll have less cooling or heating efficiency, and it could cause problems in your system in the long run.

I discuss how to choose the best MPR filter rating for your system in this article:

Air filter MPR ratings

The MPR system rates air filters on a scale of 100 to 2800 based on their ability to filter out microparticles. The higher the MPR rating, the more particles a filter blocks.

Filters with a low MPR rating are only able to filter out large particles such as lint and hair. Higher MPR ratings bring more air filtration, especially with small microscopic particles.

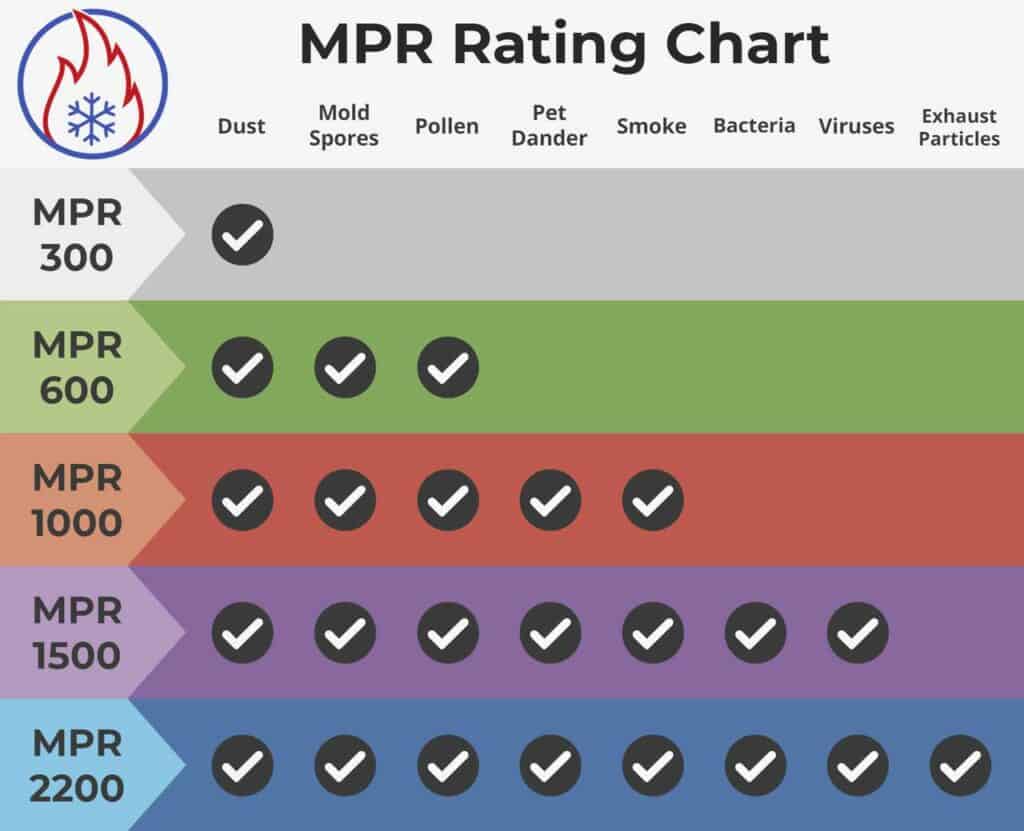

- Filters with MPR 300 rating can trap large particles such as dust.

- Filters with MPR 600 rating can capture smaller particles such as mold spores and pollen.

- Filters with MPR 1000 rating can capture pet dander and smoke particles.

- Filters with MPR 1500 rating can capture tiny bacteria and some virus particles.

- Filters with MPR 2200 rating can capture automobile exhaust particles.

Here is a chart that shows the difference between MPR ratings and what types of particles they can capture: