If you’re looking for a new fan motor for your AC or furnace, you’ll find that there are a plethora of options.

Perhaps the most important choice that you’ll need to make is whether you go with an ECM or PSC motor.

But what’s the difference between an ECM and PSC motor anyway?

The main difference between an ECM and PSC motor is that an ECM uses less energy to run. Additionally, all ECMs can run at different speeds, whereas only some PSC motors have multiple speeds.

In this article, I’ll go over the differences between ECMs and PSC motors. I’ll also discuss the efficiencies of ECMs and PSC motors, and whether an ECM is worth its cost.

ECM versus PSC motor

ECMs are a much newer technology than PSC motors.

Besides increased efficiency, ECMs also offer better range and more precise control over torque, speed, and airflow.

I’ll go over ECMs and PSC motors in more detail below.

What is an ECM?

An ECM (Electronically Commutated Motor) is an electric motor that is controlled by a microprocessor.

All ECMs have two main components:

- The motor

- The controller

In an ECM, power is provided to the controller, and the controller operates the motor at a specific speed and/or torque.

For example, a constant airflow ECM will adjust its torque and speed output in order to maintain a constant amount of airflow.

Here’s the bottom line:

The controls in an ECM increase its operational range and energy efficiency. The ECM’s controls also allow for precise control of its torque and speed to compensate for changes in air resistance in the HVAC system.

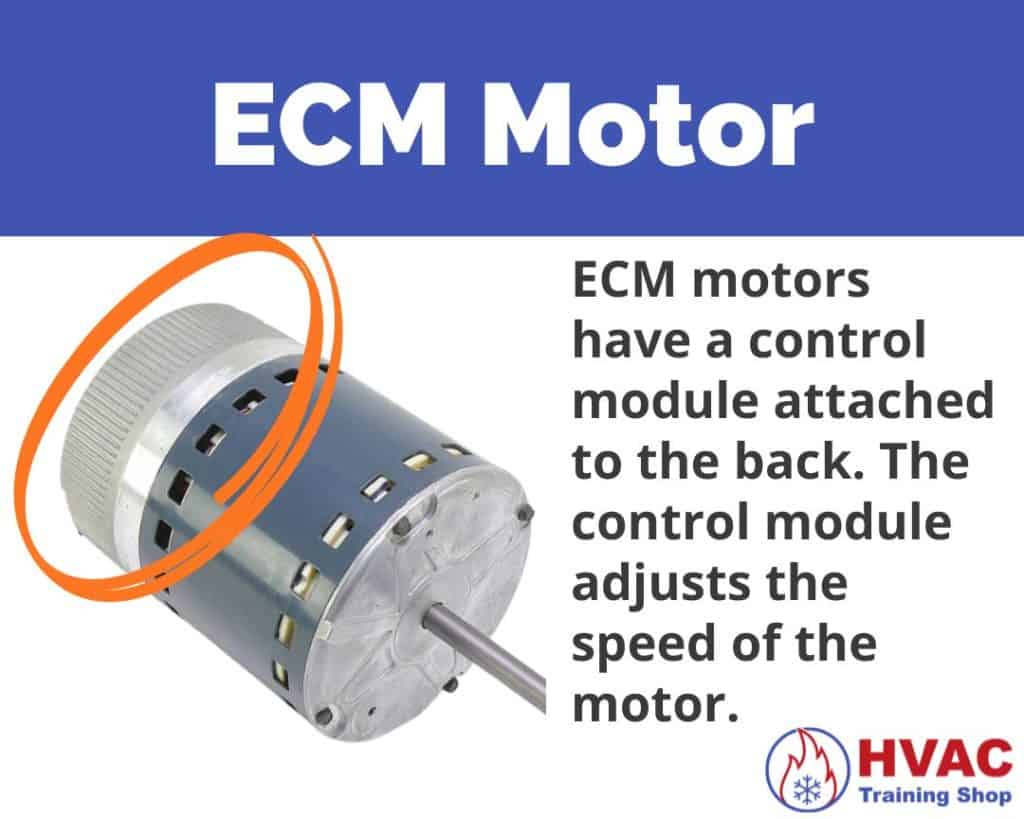

How to tell if you have an ECM

The easiest way to tell if you have an ECM is if the motor has a control module attached to the back.

The control module takes in power and outputs it to the motor windings. The control module adjusts the speed and torque of the motor in response to an input from the HVAC unit’s controller.

Another way to tell if you have an ECM is if there are two connectors plugged into the control module on the back of the motor. One of the connectors is for the line voltage input. The other connector is for the motor control signal.

What is a PSC motor?

PSC (Permanent Split Capacitor) motors have been around since the mid-1900s.

The design of the PSC motor is relatively simple: It has run and start windings, and an external run capacitor.

However, its simplistic design limits its operational range and energy efficiency. Once installed, the only output adjustment that can be made to the motor is its speed (and not all PSC motors are variable speed).

When a PSC fan motor is running, its airflow output is significantly affected by air resistance from things such as:

- Duct sizing

- Dust build-up

- Air registers and grilles

Here’s the bottom line:

Once a speed has been selected in a PSC motor, the amount of airflow produced cannot be controlled. The airflow produced by a PSC motor is at the mercy of air resistance in the HVAC system.

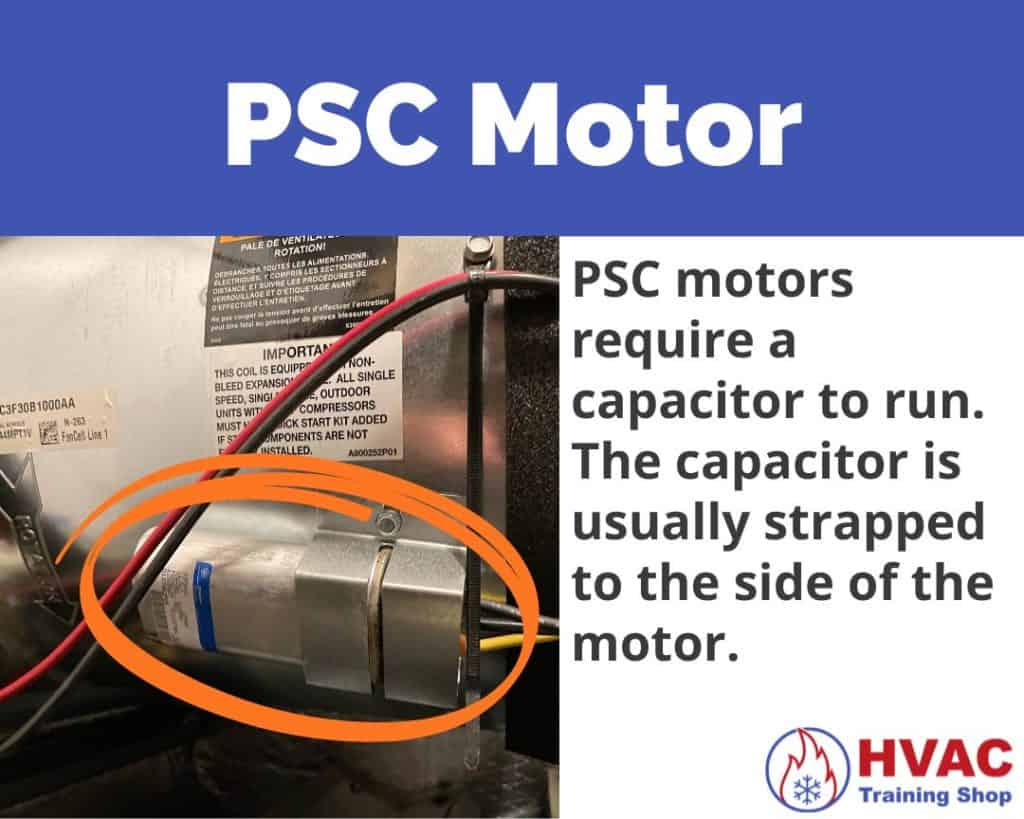

How to tell if you have a PSC motor

The easiest way to tell if you have a PSC motor is if there is a capacitor strapped to the side of it. All PSC motors require a capacitor to run.

If the capacitor is not strapped to the side of the motor, then it may be strapped elsewhere in the unit, but it will still be wired to the motor.

Another way to tell if you have a PSC motor is if it has wires coming directly out of the motor. Most PSC motors have wires coming directly out of them.

ECM versus PSC motor efficiency

- ECMs operate at nearly 80% efficiency across their entire range.

- PSC motors operate at a maximum of 60% efficiency at their rated speed and load. Additionally, the efficiency of a PSC motor may further decrease depending on its load and speed.

Benefits of using an ECM

The main benefit of using an ECM is reduced power consumption.

One study found that the use of an ECM in an AHU consumed 23% less power during heating and 38% less power during cooling when compared to a PSC motor.

But there aren’t only energy efficiency benefits to using an ECM. There are comfort benefits as well.

Constant airflow ECMs are able to maintain a consistent airflow output regardless of air resistance in the HVAC system (up to a certain point, of course). This means that an ECM is better at maintaining the rated cooling or heating output of an HVAC unit.

For example, if your air handler’s filter gets dirty, a constant airflow ECM will adjust its speed and torque to maintain your system’s rated airflow.

With a constant airflow ECM, you won’t lose cooling or heating capacity because of increased air restriction.

Is an ECM worth it?

With all the facts outlined, it’s easy to see how ECMs are superior to PSC motors in nearly every way.

However, the increased cost of installing an ECM doesn’t always offset its energy savings.

One study found that the energy savings of using an ECM was not enough to offset the cost to retrofit the ECM.

In order for the retrofit of an ECM to justify its cost, some of these conditions should apply:

- The furnace has at least 10 years of life remaining

- The furnace and cooling coil are sized correctly for the home

- Operating static pressures are low in the ductwork

- The blower is used for purposes other than heating or cooling (such as ventilation or filtration)

I’ve been in the HVAC&R for 25 years. The issue with ECM motors over a PSC motor is cost and warranty. The summer heat hits 105 degrees, and the parts house doesn’t stock the ECM motors like the PSC motors. The cost to replace an ECM is crazy to the PSC motor cost. You sure hope the ECM board and motor don’t fail and are under warranty.