Many climates have hot weather. Some places are hot year-round.

But that doesn’t mean that the inside of buildings needs to be hot.

While the temperature outside can sometimes be over 100 °F, the temperature inside the building can be a comfortable 74 °F. This is all thanks to the chilled water system.

Chilled water systems are used in medium and large-sized buildings.

Chiller plants act as a centralized cooling system that provides cooling for an entire building or even multiple buildings. This is because it is often more practical to centralize air conditioning equipment in one location rather than install many pieces of equipment in many different places.

In addition to simplifying access for a building’s maintenance crew, large water chilled systems also provide greater energy efficiency than smaller, individual systems.

An Introduction to Chilled Water Plants

Even though chilled water systems are a new idea to most people, the concept has actually been around since the time of the ancient Romans. In order to cool their buildings, the Romans would run water through the walls to cool the space inside.

It wasn’t until 1902 that Willis Carrier invented modern air conditioning. Then in 1926, Carrier invented the first centrifugal chiller, which made it possible to provide large-scale air conditioning for buildings.

Since then, chillers have undergone much innovation and there are many different types of chillers. However, the purpose of a chiller remains the same: To remove heat from water.

Chilled Water System Basics

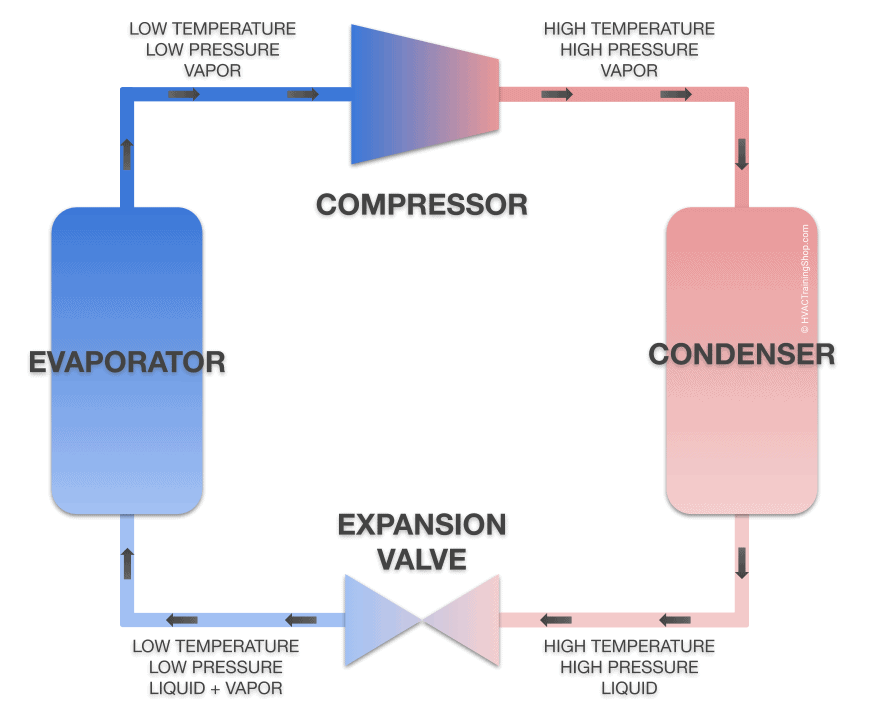

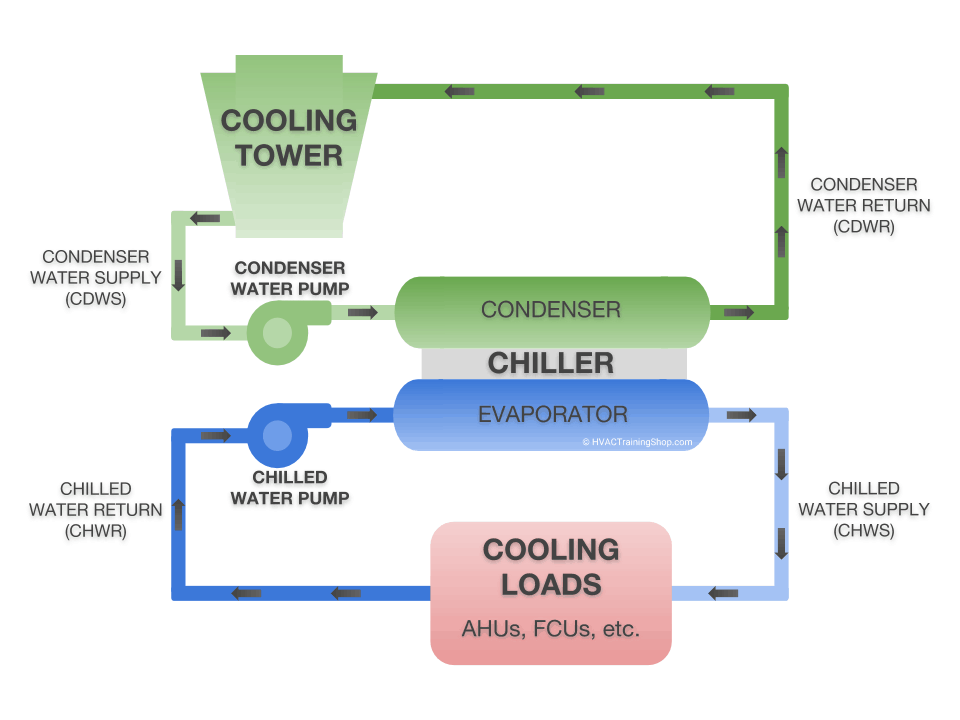

Chilled water systems provide cooling to a building by using chilled water to absorb heat from the building’s spaces. At the heart of the water chilled system, a chiller removes heat from water by means of a refrigeration cycle.

A chilled water system’s refrigeration cycle works by removing heat from chilled water in the evaporator of the chiller. The compressor is what drives the entire process. It also uses the most energy in a chilled water system.

In the condenser of the chiller, the heat is transferred to the condenser water, or directly to the outside air (we’ll talk more about this below).

Chilled Water Loop

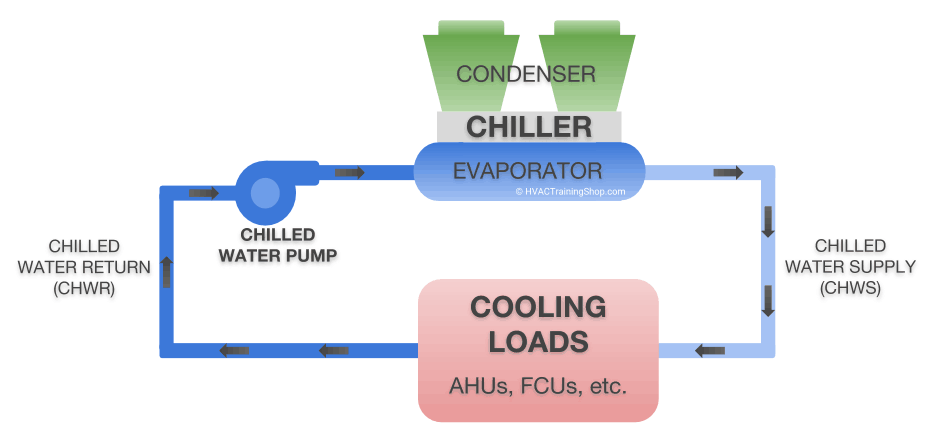

The chilled water loop consists of pipes and pumps that move chilled water around a building. A chilled water pump (CHWP) pushes chilled water through the chiller and through the chilled water line around the building.

The chilled water that exits a chiller is called the chilled water supply (CHWS). The chilled water supply temperature is usually about 45 °F.

The chilled water supply is pumped through the chiller and to the building’s various air conditioning units such as air handling units (AHUs) and fan coil units (FCUs):

- In the AHUs and FCUs, the chilled water is passed through a heat exchanging coil to reduce the temperature of the coil.

- While the heat exchanging coil is cooled by the chilled water, a fan blows air through the coil to provide cold air to the building’s space. The supply air temperature that is blown out of AHUs and FCUs is usually about 55 °F.

- After exiting the heat exchanging coil, the chilled water return (CHWR) returns to the chiller, where it is cooled again, and the process repeats.

Some chilled water cooling system configurations are very simple, while others are more complex:

- A simple chilled water cooling system configuration can consist of a single chiller and a single pump.

- A more complex chilled water cooling system configuration can consist of multiple chillers, multiple pumps, cooling towers, heat exchangers, and all sorts of valves to redirect flow according to the heat load inside of the building.

Next, we’ll talk about a couple of different chilled water system configurations.

Chilled Water Cooling Systems

When a chiller is producing chilled water, the heat that is removed from the chilled water must be rejected somewhere – usually outside of the building. The chiller system is the facilitator of heat transfer between the inside and outside of a building.

There are two main types of chilled water cooling systems: air-cooled chillers, and water-cooled chillers.

Air Cooled Chiller

Air-cooled chillers are almost always located outside of a building and remove heat from the chilled water by exhausting the heat directly to the surrounding air.

Air-cooled chillers exhaust heat from the condenser coil. As warm refrigerant passes through the condenser coil, the outside air blows over the condenser coil and removes heat from the refrigerant.

The refrigerant then passes through an expansion valve, where it rapidly cools and goes through the evaporator, where it cools the chilled water. This process is then repeated all over again.

Water Cooled Chiller

Water-cooled chillers are almost always located inside of a building. They work almost the same way as air-cooled chillers. The difference is that they remove heat from chilled water by exhausting the heat to a second, isolated water line called the condenser water line.

The condenser water flows through the chiller and picks up heat. The condenser water then returns to the cooling tower. The cooling tower is almost always located outside of the building and removes heat from the condenser water by evaporating some of the condenser water into the atmosphere.

As some of the condenser water evaporates, heat is removed from the condenser water, and the cool condenser water flows back to the chiller. This process is then repeated all over again.

Water-cooled chiller systems are very energy efficient. However, due to their complexity and many different parts, they are often more expensive to install and maintain. For this reason, you will usually only find them in large buildings. This is because the energy savings outweigh the cost of installing and maintaining the system.

However, water-cooled chillers are starting to make an appearance in small buildings as well. Recent advancements have made it practical to install and maintain water-cooled chillers in buildings that usually would not have one.

Chiller Plant Optimization

Chiller plants are often a significant portion of a building’s energy usage. According to the U.S. Energy Information Administration, 15% of the energy used in commercial buildings is for cooling.

When you consider that chillers are often one of the largest consumers of energy inside a building, their performance can have a huge impact on operational costs. For this reason, the efficiency of a chiller plant is often closely monitored for potential improvement.

Optimizing a chiller plant is a complex task that involves gathering data and making calculations. These calculations determine how to best operate the chiller plant equipment.

For instance, during the cool night hours, it may be more efficient to raise the chilled water supply temperature setpoint of the chiller. Raising the chilled water supply temperature setpoint will allow the chiller to not work as hard.

Conclusion

Chilled water systems are typically used for cooling medium and large buildings. While the upfront cost of a water chilled system can be a lot, the greater energy efficiency and lower maintenance costs usually make up for it.

A chiller is simply a facilitator of heat transfer between the inside and the outside of a building, and the chilled water system can have many different configurations. Air-cooled chillers and water-cooled chillers are the most commonly used types of chillers.

Next, check out this awesome video that shows the operation of a chiller plant: